“There’s six different crystal structures that the cocoa butter could take as it warms, or cools, but there’s only one shape that creates the perfect stack of chairs. That’s why the chocolate has to go back and forth between 82 and 89 degrees.

“But keep in mind that different types of chocolate will have slightly different top and bottom temperatures for tempering. That’s why I have all these refiners and tempering machines, the white, dark, milk, all have slightly different requirements.

“Plus, I don’t want to get my Belize chocolate mixed up with my Haitian chocolate.”

We’ve been forced to leave Belize after only nine months of our year-long adventure and have found ourselves staying with a good friend in Phoenix, Arizona. And through a stroke of good luck we’ve met Denae Hostetler, owner of DNA Chocolate, a bean to bar shop that uses Belizean cacao beans for her bars, blocks, batons, and other goodies. Haitian cacao is used for her milk chocolates, syrups, and hot chocolate mix.

Of course, we’ve ended up in her small shop, behind her Chandler, Arizona home, in a former guest house that Chris, her mechanically gifted husband, converted for her.

“Would you care for a few samples?”

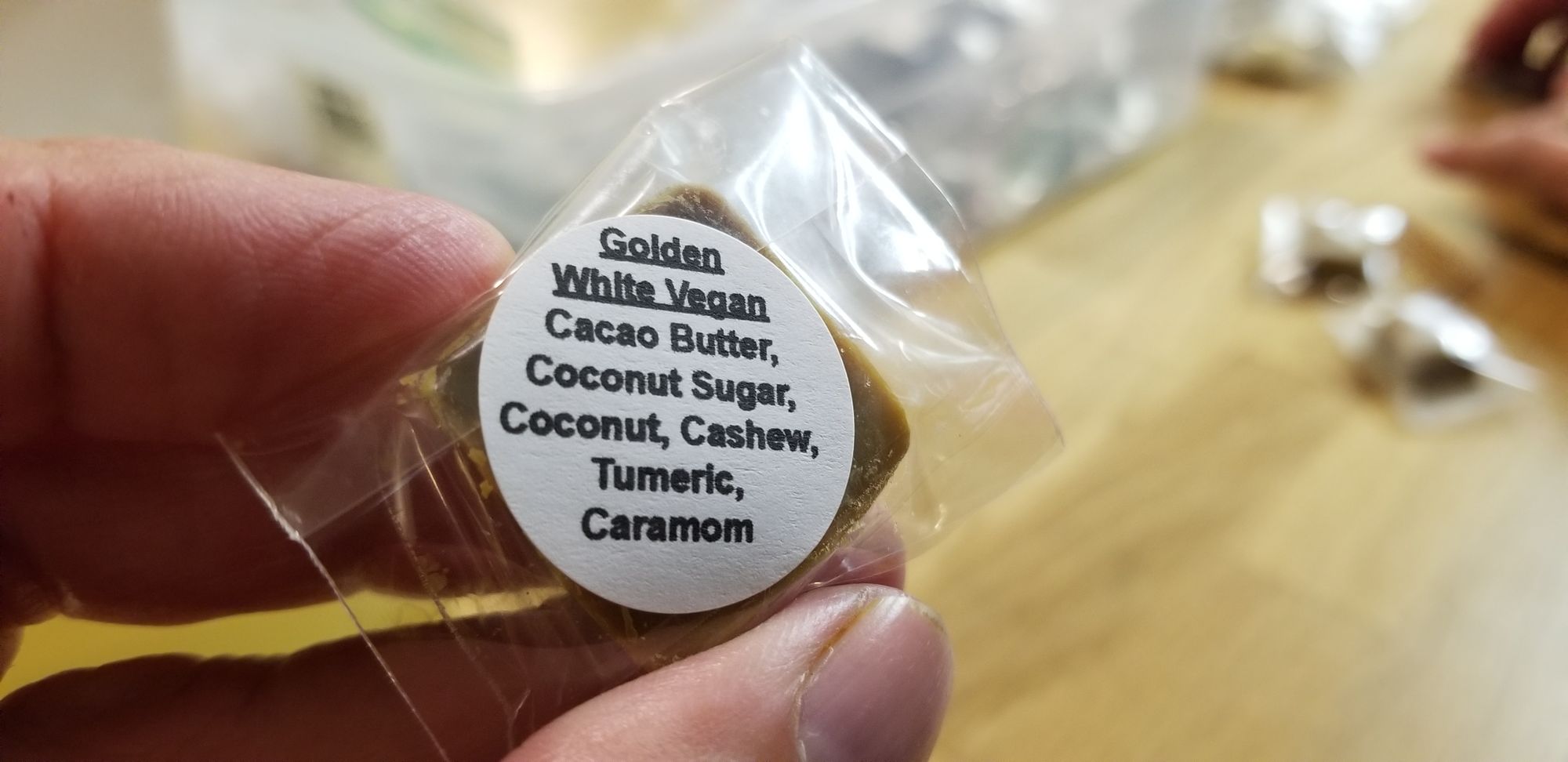

Denae opened a large plastic box full of small chocolate bites, some flavored with turmeric, coconut, cardamom, or cinnamon. Each is individually wrapped and labeled. They’re samples for prospective clients, and there must be a couple hundred of them, and she offered us as many as we care for. Yikes!

Since we have a couple of months before our renters leave, we’ll take take our time driving home and visit some craft chocolatiers along the way. Because maybe a bean to bar shop is in our near future. Our first week in Phoenix we bought a couple of chocolate croissants from Proof Bakery and we both thought the chocolate tasted familiar, my wife recognized the red plum and raspberry notes of Belize, and I asked the baker where they procured their chocolate. When I asked Denae about her relationship with Proof, she mentioned how critical they are to her success.

“Proof has been great to work with and although the batons I sell them aren’t very profitable, the word of mouth I receive every time someone bites into one of their sourdough chocolate croissants is priceless.”

Sourdough bread and Belizean chocolate. What’s not to love about that?

Denae’s been a fan of Belize chocolate for quite some time and buys cacao through the TCGA – Toledo Cacao Growers Association – and the Toledo district in Southern Belize is where most of Belize’s cacao is grown.

DNA has been around for almost nine years, and she’s really developed her business, from going after businesses celebrating a milestone and offering celebratory chocolates, to making chocolate syrups for a bustling coffee shop. Her collection of small refiners and tempering machines has grown over the years, likewise her family of upright refrigerators, each stained with that lovely shade of brown only cocoa powder can produce.

Her workspace is tattooed in Sharpie black; roasting times for the different beans share space with reminders to purchase new granite wheels for the refiners, pick up coconut sugar soon. Denae opened another box, and more samples were before us. These were Gianduja style bites with a hazelnut in the center and again she invited us to have as many as we like. Her hot cocoa mix is all Haitian chocolate and she tried using Belize or cacao from Chiapas, Mexico but those were much too forward, too strong for what most of us would consider for hot chocolate.

“I started small, kept my costs low by doing everything and as the business grew, I hired one or two others to help out. Now I’m to the point where I have people that love to make chocolate, and we’re a great team.” She finished that sentence then offered us a word on gluten-free. “I use malted rice flour in my malted chocolates. And staying gluten free and specializing in Belizean cacao keeps me above the multitude of mediocre chocolates. If you get into this business model, every day you’re going to field those questions about where your beans are from, what kind of sugar, is there any gluten, etc. And if you keep your chocolates as pure and simple as possible, you’ll stay above that crowded field of cheap chocolates.”

The bean to bar business model is what, fifteen years old? Competition brings more exposure and exposure brings more interest in better chocolate. More people interested in craft chocolate will help create more craft chocolate shops. Our town of Greenville, SC has two craft chocolatiers and we’re wondering, thinking, planning if it could support a third, and what would that shop look like if we expect it to support us.

“Just remember to charge more than thirteen per pound. It took me a while to figure that out because my cost of goods is never stable. Thirteen dollars a pound, that’s my break-even point.”

Wow. Thirteen dollars. Shipping, packaging, and all those raw ingredients are in a state of flux right now and that dollar amount is rather daunting. Denae’s husband has built her a 3D printer and she has a variety of molds, colorful packaging, and a nice assortment of value added products, like her hot cocoa mix. She has been able to turn a profit through the clever marketing of not just her handmade chocolates, but through sales of those items on the periphery. And even though we’ve only known one another for less than two hours, she has been quite gracious with her time and knowledge.

“I may not know the answer to your question, but I’ll know someone that does. Should you have questions y’all just reach out to me.”

While we were saying our goodbyes, she offered us a new batch of samples, hexagonal chocolate discs centered with a dried banana slice and the reverse side wore her DNA logo. This one resembles one of those grand medals a heroic soldier or sailor would wear.

The hexagon is purposeful though, it refers back to that crystalline structure her chocolates achieve, and any shelf-stable artisan chocolate should aspire to. DNA Chocolates can wear that medal proudly.