Updated: The Impact of Fermentation Research & Quality | #PSC 172

Episode 172 of #PodSaveChocolate takes a look at research on cocoa fermentation published in 2025 (with some context from 2021). Is it useful? Usable?

When and Where to Watch

Links below to watch LIVE and to view the archived episode.

Watch and comment LIVE or view the archived episode!

Subscribe (free!) to the @PodSaveChocolate YouTube channel, like this video, comment, and share this episode to help grow the #PSC community.

Watch and comment LIVE or view the archived episode on LinkedIn. Join my network on LinkedIn to receive notifications and to refer business to each other.

Watch and comment LIVE or view the archived episode (for 30 days from the date of the livestream; thereafter on YouTube) on TheChocolateLife page on Facebook. (Follow TheChocolateLife on Facebook to receive notifications and catch up on other content.)

Overview - Episode 172

Episode 172 of PodSaveChocolate examines one of the crucial steps in the cocoa-to-chocolate production process: fermentation. 2025 saw some fascinating new research, especially when it comes to identifying specific microbial contributors to flavor.

Note: There has been field work on fermentation approaches that have NOT been published in peer-reviewed journals. That field work will not be discussed here as there is no independent review of the findings. That does not mean the field work is not important or has no value, just that the reported results (many of which have amassed anecdotal support) have not been peer-reviewed.

Before We Begin – The TL;DR on the Market

- Share: Fine/flavor cocoa represents ~5–8% of global production; historical references cite ~9% (~263,000 MT in 2017).

- Tonnage: Applying 5–8% to recent world output yields an indicative range of ~250,000–400,000 MT annually.

- Pricing: At a daily price (average) of about ~US$6,000/MT; fine/flavor typically commands ~20–30% premiums.

- Value: Estimated market value band ~US$1.7–3.0B, derived from 240,000 MT × US$7,200/MT and 384,000 MT × US$7,800/MT calculations.

- Reporting: ICCO’s Ad Hoc Panel classifies origins as fine/flavor; ICCO does not publish a standalone annual fine/flavor tonnage series in public datasets. Authoritative production and price series are in the Quarterly Bulletin of Cocoa Statistics.

- There is still value in pure research that is independent of market applicability or acceptance.

The TL;DR (Fermentation)

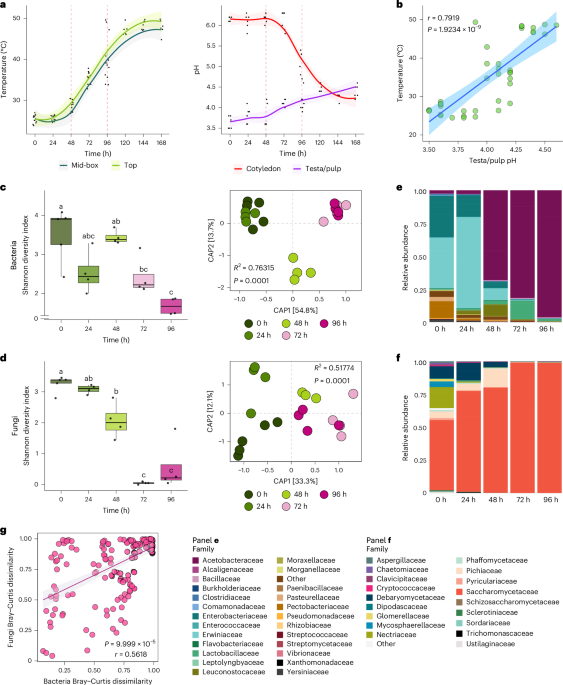

What fermentation is doing inside and outside the bean

- Outside (in the pulp): Yeasts first digest sugars anaerobically, producing ethanol and heat; pectins break down so the mass drains and oxygen enters. Lactic acid bacteria flourish early; then, with more oxygen and rising temperatures, acetic acid bacteria convert ethanol to acetic acid. This acid and heat diffuse inward.

- Inside the bean: Heat and acids kill the embryo, membranes rupture, and stored substrates mix. Enzymes (aspartic endoproteases and carboxypeptidases) begin selectively cutting storage proteins (especially 7S vicilin globulins), releasing hydrophobic amino acids and short peptides—the building blocks for Maillard reactions during roasting. Polyphenol oxidase and peroxidase drive oxidation of polyphenols into tannins, reducing astringency and bitterness.

Why temperature and pH matter most

- Enzyme sweet spot: The proteases that generate aroma precursors are most effective when bean pH sits roughly 5.0–5.5; peroxidase activity is strong around ~5–5.5. Keep pH too low for too long and proteolysis stalls; too high and oxidation to tame astringency lags.

- Thermal profile: A rapid early rise (as yeasts work) followed by a controlled mid-phase temperature helps both microbial succession and enzyme kinetics. Sustained, moderate warmth promotes polyphenol transformation and protein breakdown without baking the mass or trapping excessive acid.

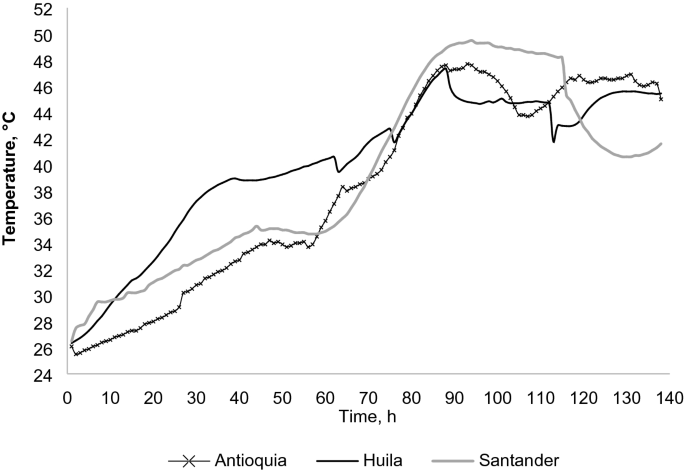

Typical dynamics observed

- Pulp total soluble solids plunge in the first 48–72 hours; lactic and acetic acids peak around days 2–3 and then diffuse into beans.

- Bean pH falls early and should recover toward ~5–5.6 by the end; proteins drop ~12–16% as amino acids are liberated; epicatechin, catechin, and procyanidins decline substantially, cutting astringency; fats and fatty acid profiles barely change.

How these trajectories shape flavor

- When bean pH rebounds into the ~5.0–5.5 window near the end, protease + carboxypeptidase synergy yields a richer pool of precursors—more cocoa and nut notes after roasting, with less bitterness/astringency.

- Too cool or poorly insulated fermenters lose heat, slowing succession and enzyme action, often yielding flatter, more acidic profiles.

- Too acidic (pH < 4.75 prolonged) or excessively hot/poorly ventilated runs can lock in sharp, vinegary notes and suppress desirable complexity.

Practical signals to watch during a heap or box fermentation

- Temperature: Track core-mass temperature, aiming for a brisk early climb and a stable mid-phase plateau rather than spikes or long cool periods.

- pH: Measure bean (or cotyledon slurry) pH daily; a healthy curve dips and then returns toward ~5–5.6.

- Draining/aeration: Good pulp drainage and timely turns improve oxygen ingress, supporting the acetic phase and acid clearance.

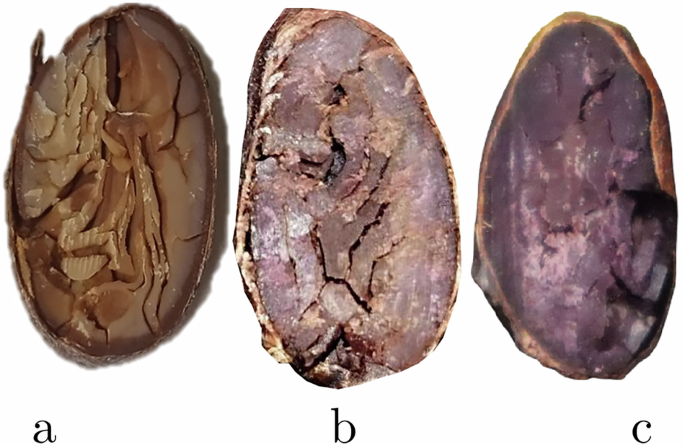

- Cut test: Progressively browner beans indicate internal reactions are advancing; purple/grey suggests under-fermentation.

Nuances worth noting

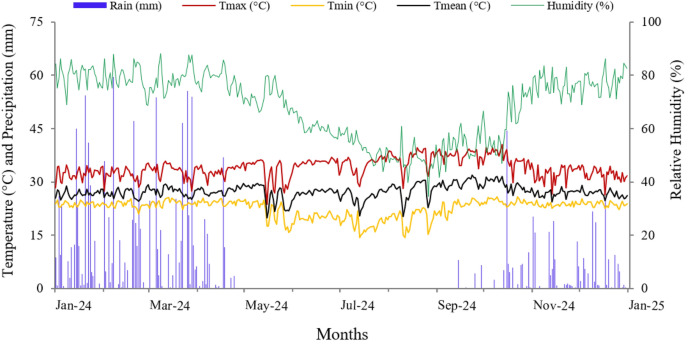

- Optimal temperatures are phase- and origin-dependent. Field data often favor averages near ~40°C; controlled studies sometimes show benefits from mid‑40s °C late in fermentation if pH is managed and ventilation prevents over-acidification.

- Genotype, maturity, ambient climate, and box design (size, insulation, airflow) all modulate heat retention and acid dynamics—so “right ranges” should be tuned to a specific locale and infrastructure (e.g., box, tray, heap) rather than copied wholesale.

Research Published in 2025

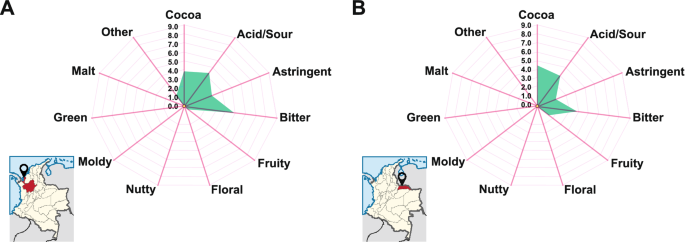

Colombia

TL;DR: Defined, metabolically competent starter cultures can reliably reproduce and tune fine-flavour chocolate under controlled fermentation, enabling industrial consistency while retaining origin-linked diversity.

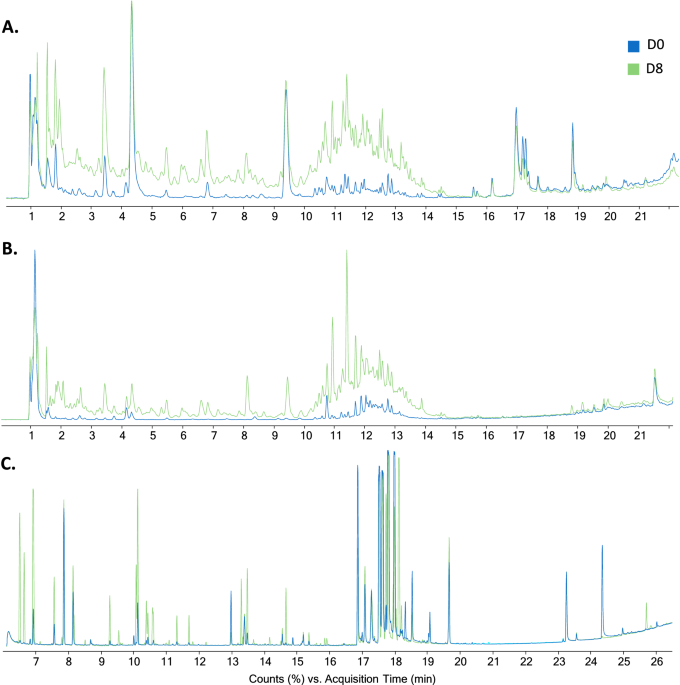

Brazil

TL;DR: Fermentation creates sensory precursors while trading off certain antioxidants and minerals; NF (non-fermented) retains bioactives but shows higher oxidative markers. Clone responses are genotype-dependent, enabling targeted selection and blending strategies to balance flavor and functionality. The overall implication: choose clones and fermentation regimes deliberately—CCN 51, EEOP 63, CEPEC 5, EEOP 96 emerge as strategic options—to optimize both product quality and health-related traits.

Antioxidant “health” messaging should avoid overreach: fermentation reduces certain polyphenols; NF retains them but also shows higher oxidative markers (MDA) and lower enzyme-mediated defenses; net functional impact depends on downstream processing (roasting, alkalization), dose, and bioavailability.

Mineral enhancements in F(ermented) (K, Mg) are context-dependent; reported directions vary by fermentation system and turning/leaching dynamics; specify process conditions if making nutritional claims.

Colombia – Hyperspectral imaging is an approach I have been promoting since 2018 as a way to improve quality assessments

One Key Result: Regulatory relevance – the inclusion of cadmium measurements aligns data utility with EU 488/2014 compliance analytics for export markets. This enables model development that flags high‑risk lots before processing

2021 – My deep dive on cut tests.

Multi-country study; when combined with hyper-spectral imaging these two techniques can very quickly identify smuggling.

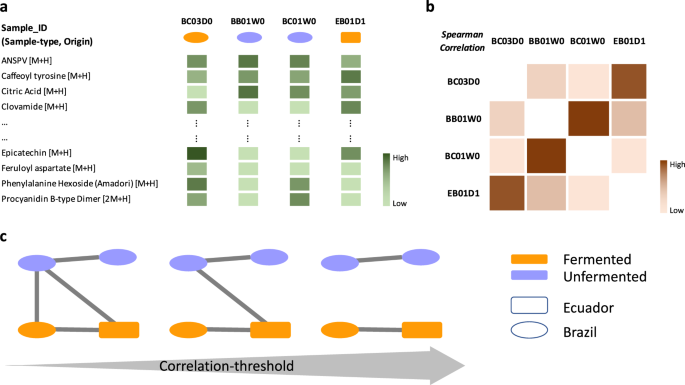

TL;DR: correlation networks of LC-MS profiles provide an unsupervised, scalable framework to fingerprint cocoa by stage first and origin second as correlation thresholds increase.

Related Research

2021

2021

2021

Other Coverage

See also episode 68 – Cacao Fermentation 101

Bertus Eskes' cocoa fermentation research focuses on innovative methods like Anima, Tradima, and TropMix, which aim to create high-quality fine cocoa and unique flavors by manipulating pulp environment, sometimes adding fruit pulps or spices to develop specific aromas and reduce reliance on traditional Dutching, revealing 43 natural flavors and 31 fruit/flower traits in cocoa, with data available through his publications and interviews on platforms like The Chocolate Life(!) and ResearchGate.

Summary Tables

Fermentation Process Overview

| Metric | Value/Range | Notes |

|---|---|---|

| Fine flavor cocoa market share | 5-8% of global production | Historical references up to 9% |

| Fine flavor cocoa annual production | 250,000 - 400,000 metric tons | Based on 5-8% range |

| Price premium for fine flavor cocoa | 20-30%, up to 50%+ | Depends on genetics, producing country, fermentation method |

| Price range per metric ton (example) | $7,200 - $8,000 | Based on $6,000 commodity cocoa price + premiums |

| Estimated market value | $1.7 billion - $3 billion | For fine flavor cocoa market |

| Overall chocolate market size | $180+ billion | Specialty cocoa is a small niche in comparison |

Quantitative Data and Market Overview

| Stage | Microbial Activity | Key Chemical Changes | Impact on Bean |

|---|---|---|---|

| Initial (Anaerobic) | Yeasts ferment sugars → ethanol + heat | Pectin breakdown, pulp liquefies (TSS drops) | Heat and ethanol penetrate bean; embryo killed |

| Mid-phase (Aerobic) | Lactic acid bacteria flourish | pH changes; lactic acid production | Enzymes activated inside bean break down proteins and sugars into flavor precursors |

| Late-phase (Aerobic) | Acetic acid bacteria convert ethanol → acetic acid | Acetic acid and heat diffuse inward | Oxidation of polyphenols reduces bitterness and astringency |

Comments? Questions?

If you have questions or want to comment, you can do so during the episode or, if you are a ChocolateLife member, add them in the Comments below at any time.

Episode Hashtags and Socials

#ferment #fermented #fermentation

#cocoa #cacao #cacau

#chocolate #chocolat

#specialtychocolate #craftchocolate #beantobar

#PodSaveChoc #LaVidaCocoa #TheChocolateLife

Future Episodes

Why Agriculture? Was it Fermentation? Beer?!

#PodSaveChocolate and #TheChocolateLifeLIVE Archives

To read an archived post and find the links to watch archived episodes, click on one of the bookmark cards below.

Episodes 101-current

Episodes 1-100

All 146 episodes