Which Is The Best Grinder/Melanger To Buy? (Updated)

Updated: Feb 6, 2022. Originally posted in May 2017, this post continues to be one of the most popular referrals from search engines.

As with most things cocoa and chocolate, the answer is, “It depends.”

These days, you can purchase melangers (from melangeur, French for “mixer”) in a wide range of sizes from 2kg lab-scale table top machines to ones with batch capacities of 100kg or more.

Accompanying the many different size options are choices about the granite used, how pressure gets applied, how easy or difficult the melanger is to clean, and more. These sometimes subtle (and sometimes not-so--subtle) differences, many of thich affect price, complicate the decision about which melanger to buy,

It is also important to understand that most melangers are, in fact, used as Universals – all of the processes of converting nibs, sugar, and other ingredients into finished chocolate are done in one machine. However, melangers were not originally intended to be universals.

Melangers are not Conches

Even though manufacturers call them that

Added Feb 20/2022

While melanger means mixer, in fact it is the particle size reduction (grinding and refining) capability of the melanger that is of most interest to chocolate makers. Mixing is achieved through the motion of the ingredients under the grinding wheels, boosted by rotational motion.

Conches, on the other hand, do not perform any particle size reduction through grinding. Instead, agglomerates (clumps of particles) are broken apart and individual particles are coated with fat. At the same time, the temperature of the chocolate, in conjunction with forced heated air, speed up the evaporation of volatile acids.

While melangers can conche, they do so inefficiently. Results that take 36-48 hours or more in a melanger can be achieved in a purpose-built conche in under two hours with no obvious differences in quality.

Drive Mechanism

There are both indirect and direct drive mechanisms. In a machine with an indirect drive, the motor is connected to the drum spindle by a belt or chain. In a direct drive mechanism the shaft of the motor is directly connected to the drum spindle. This motor can be below the drum or above it.

From a mechanical perspective, direct drives are more efficient than indirect (or offset) drives and are worth the added expense.

- If the machine you are looking to purchase has an indirect drive, metal chains are better than belts because belts have a tendency to stretch and loosen over time.

- If the machine you are looking to purchase has a belt drive replace the belt with what is called a link belt. These are much easier to install, and run with less vibration.

Variable Speed

The ability to vary the rotational speed of the drum is very useful as it is one way to control temperature.

The same electrics used to vary the speed of rotation should also be able to reverse the direction of rotation of the drum; this is useful on larger machines in case things get jammed up for any reason – like backing a car out when a wheel is stuck in the mud.

Pressure Mechanism

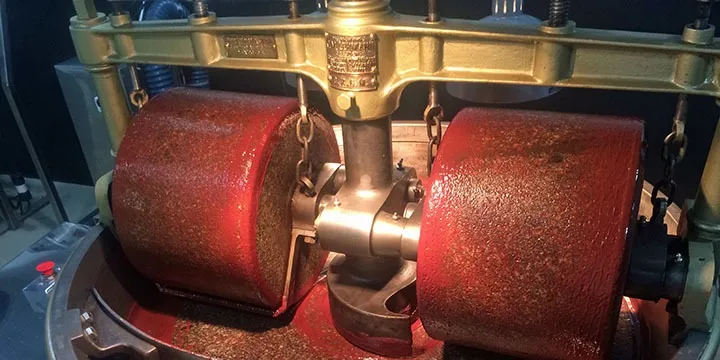

The original method of applying pressure in a melanger is dead weight. Take a look at the photo at the top of the page. The two stones each weigh hundreds of kilos. In modern melangers, a pressure mechanism replaces the dead weights.

The most common pressure mechanism found on wet grinders is a spring-loaded tensioner that exerts pressure on the vertical shaft holding the axles for the grinding stones. Another, newer, pressure mechanism is pneumatic cylinders that has separate pistons for each grinding stone.

There are two things to consider with a spring-loaded tensioning mechanism:

- It can be a challenge to get the same pressure on the stones from batch to batch. Differences in pressure can result in differences in grinding time – which can affect the rheology (viscosity and flow characteristics) of the chocolate. These differences – if large enough – can lead to different tempering parameters being needed. This is less likely to be a factor when batch tempering but can easily show up when using continuous tempering machines.

- Too much tension (pressure) can led to bending the axles out of true or causing the grinding wheels to not sit flat on the base as there will be more pressure on the inside edge. This will lead to reduced grinding efficiency and uneven wear of the grinding wheels and the base. And, pointing out the obivous, all that worn stone is dust in your chocolate.

Bowl Geometry

It is very often the case that when you line up two or more bigger (10kg and above) wet grinders it is hard not to notice that the bowls wobble out of true. This has the potential to change the flow of chocolate inside the bowl leading to slight differences in the processing characteristics.

Not that there is much of anything you can do about it, but it is something to be aware of.

If you take a look at the photo at the top one thing that is not obvious is what turns. In that case, there is a granite platform with a steel lip that turns within a protective base. The base is rotated by a motor and the grinding wheels turn when they are in contact with the platform.

There are modern melangers where the base and bowl do not turn. The motor is attached to the top of the grinding wheel mechanism and it is the wheels that turn and everything else remains stationary. The primary design consideration here is safety.

Bowl Heaters

These are mechanisms that raise the temperature of the stone and have the effect of reducing the amount of time required to start expressing the fat from the nibs. Heaters have the effect of reducing the amount of time to required to complete a batch and, when combined with a fan to increase air circulation, can speed the evaporation of unwanted volatiles.

Care needs to be taken because it is easy, when using forced hot air over extended periods of time, to evaporate off volatiles too effectively, resulting in a chocolate that smells and tastes flat.

The Original Question and Responses

Which is the best Grinder/Melanger to buy? Choosing one is proving difficult, I think I have basically narrowed it down to either a spectra or a cocoatown, they seem to do the same things but are very different in price. In desperate need of help to choose!! I should also note I am in the UK.

I think this user is just a spammer…

I have to agree with Choklat when he says that if you are going to be buying a wet grinder for chocolate you want one made to make chocolate. Most small wet grinders are made to work a short time.

Is any of the models listed suitable for making chocolate? I notice you have buy links on the page so I want to make sure that members know what they are clicking through to.

Sarah – These small table top wet grinders were designed as kitchen appliances and are not designed to run for 8-12 hours or days at a time. It’s best to look for ones that have been modified (e.g., critical wear parts in plastic parts upgraded to metal) for making chocolate. I also think of these as lab machines, not production machines, as they are too small to make chocolate cost-effectively to support a profitable business.

I found good option for me on this site: https://cookingtimejournal.com/best-table-top-wet-grinders. This article is new, so information is relevant. I hope you’ll find what you need.

02/19/14 06:52:38PM

James:

There are many ways to make chocolate from the bean. The route that most small startups take is using a so-called wet grinder as a “universal” – a grinder/refiner/conche. The reason for going this way is simple – it’s very inexpensive to get started.

The wet grinder uses two grinding stones against a stone base. Pressure is exerted on the grinding stones which takes the very large particles of cocoa and sugar and refines them to the desired size while at the same time doing flavor and texture development.

Now, there’s no need to fixate on 15 microns – it’s not just the particle size, it’s the particle size distribution, which looks a lot like a bell curve. No matter what you do in a wet mill you are going to get a distribution of particle sizes – some will be larger than the center/peak and some will be smaller. The location of the peak and the shape of the curve are related and important. It’s also important not to have too many particles that are too small as this can make the chocolate gummy and pasty.

Now that that’s out of the way.

The real engineering differences between the small tabletop Santhas and CocoaTowns are not all that great. They have small motors (too small), tend to have lousy drive belts, and plastic parts that wear down quickly. The main difference is in the way pressure is applied. The Santha has a knob you turn (adjustable) and the CocoaTown has a spring-loaded lid. There are lots of posts here on TheChocolateLife about the replacement belts and bushings for the small machines.

One of the main price differences you’ll see between the CocoaTown and the Santhas has to do with size. The CocoaTown comes in one large size (a 65 liter working bowl). The Santha has more sizes; the 20 and 40 liter machines are the most common. The size difference accounts for most of the price difference.

Well – not really. When you buy a Santha Spectra 40 it comes with an electronic speed controller. When you buy a CocoaTown ECGC65L it does not.

So which is better? It’s hard to say. If you are just starting out, you’re probably best off with one or three of the small tabletop machines to learn the process so to speak. Once you’re comfortable that you know what to do and that you have a business, it’s really all about how much production you need. If you are doing 200kg a month that’s one answer. If you’re doing 200kg a week it’s a different answer. If you’re at 200kg/week or more you also want to start thinking about bringing other machinery into the mix – a pre-grinder for the nibs and sugar and a dedicated conche so you’re using the wet mills only as grinder/refiners — or, you’ve moved on to an entirely new suite of equipment.

:: Clay

—

@Sherill

02/19/14 08:55:24PM

Thanks so much Clay for this. As with James, I’ve had the same dilemma and this information helps a lot. I am a silent member of this wonderful site and has been greedy of all the informations all the members has been generous of.I guess, it won’t matter which machine to choose from as long as it does the work and gives you the result you need. Kudos to you Clay and all the members. Cheers!

—

@Liz Rowe2

02/23/14 08:40:38PM

I’ve got a Spectra 40, but don’t think it grinds nearly as well as my benchtop Spectra 11. One thing I’ve wondered is about whether I need to ‘scale’ the time in the bigger grinder given the fact I’m doing bigger loads and, if so, how to scale. For example, does 3 kilos for 10 hours in the Spectra 11 equal 9 kilos for 10 hours in the bigger machine, or 9 kilos for somewhere nearer 30 hours?

—

@Lee2

02/24/14 08:25:19AM

The Premier Wonder gets the thumbs up from various people including Chocolate Alchemy … I’m pondering getting one.

—

@James Hull

02/25/14 03:45:33AM

Hi Clay, thank you for your helpful comment. I have since been looking at the tabletop versions, and have decided its best to practice with one of these. However I am now undecided on the spectra 11 or the cocoatown ECGC-12SLTA both seem very similar but I think the spectra is cheaper for some reason, but doesn’t come with warranty if used for chocolate? James

—

@James Hull

02/25/14 03:48:25AM

Hi Lee,I have been looking at the machine you suggested and seems easy to get hold of in the uk, but it seems that people are unsure whether it would overheat if run for too long?

—

@Lee2

02/25/14 06:19:30AM

I’m in the same position as you I’m afraid. No idea! Based on what I’ve read here on TCL and the user’s thread on the chocolate forum at proboards it seems like a winner. Price is right too! Seems to me overheating is not a big deal. Just rig a fan to blow on the motor.

—

@Potomac Chocolate

02/25/14 01:25:58PM

I’ve run many test batches in a couple of unmodified Premiers for multiple days with no heat issues. I also haven’t heard of anyone having any problems with them overheating.

—

@James Hull

02/25/14 01:33:38PM

That is brilliant news as it would seem that they bar far the cheapest machine. I was wondering why they are so much cheaper though…Which premier do you have?

—

@Potomac Chocolate

02/25/14 01:54:45PM

I have the Premier Wonder Grinder which is the non-tilting 1.5 L version.

—

@Gap

02/25/14 04:38:54PM

I have the same machine and have left it running for 50 hours straight without any fans/modifications. No problems what-so-ever. My machine would have done over 800 hours now without needing new belts or any new parts.

—

@James Hull

03/03/14 10:53:05AM

After your advice and recommendation I am going to go for a premier grinder. From what you and Gap have said the 1.5ltr machine seems to have no problems running for long period of times and has good durability. I was wondering whether or not you have tried/tested the slightly larger premier 2ltr grinder (tilting and no-tilting version)to see whether it is as good as the 1.5ltr one.

—

@Beryl Wells Hamilton2

03/07/14 10:54:25PM

Hello. We love our Premier Grinders. We do four single origin chocolates in very small batches, so these small machines work very well for us. We also like being able to back off the stones so the chocolate stops grinding but keeps conching. After several hundred hours, the belt got a bit loose so the chocolate was conching but not grinding/refining the particle size down enough. We opened the top, loosened the nuts that hold the motor in place, adjusted the motor so the belt was tight, and tightened the bolts. Problem solved.

We also want to add our thanks to those on this forum who have contributed so much information and advice. We would not be making bean-to-bar chocolate without you.

—

@Lee2

03/19/14 06:27:37AM

Have you asked over at the chocolate alchemy forum (aka chocolate talk proboards)? They have a whole thread for Premier Wonder owners.

—

@Samson

08/14/14 09:40:27AM

Thanks a lot for information, Clay! That is right i needed, very useful for me!

—

@Samson

08/14/14 09:48:05AM

Unfortunately, we have not such a wet grinders here, in Georgia. Can anybody advice where is possible to buy one in internet by reasonable price and in good quality?.. Except cocoatown.com and amazon.com

Thanks.

—

@Victor Kudryavtsev

08/14/14 06:35:25PM

10 80 . , . . 21 . http://www.youtube.com/user/Kudvic/videos

—

@Geo

04/04/17 07:25:44PM

My good friend Victor died at age 54 and Kudvic does not make the bean to bar equipment any more. Beware of scam.

—

@cristiansilva07

05/20/17 07:07:07PM

Hey!

I am in the proccess of making my own machine but i do not know the name of the stone…. i mean, i imagine that should be a special stone. Anybody know the name? or what kind of stone can i use

THANK YOUUUUUUUU!!!!