For 9 years we have been making absolutely fabulous chocolate. However we haven’t been doing it with the stone wheeled “Melangeurs” that craft chocolate makers have been using. Why is that? Well, to be very candid with you, the stone wheeled melangeurs are actually designed to mill grains and seeds, and are not designed to make chocolate. They never were.

On top of that, using stone mills to grind cacao beans is based on technology that hasn’t been used to make chocolate now for many years. This is why the larger melangeurs are not being made anymore and are extremely hard to find (although rumour mill has it that a company has started producing them again in Europe).

True Story.

9 years ago when I first started Choklat (www.Choklat.com) I rolled the dice and purchased a couple of these JMJ40 machines from a company in China. They made amazing chocolate, so I bought a couple more. The 4 small machines we’ve been using here at Choklat have been running 24/7 for 9 years, and the only thing we’ve had to replace have been the heating elements.

They are rock solid. They have made us several million dollars worth of chocolate. Best of all? They are priced about the same as the stone wheeled melangeurs.

You can buy a grain mill from an equipment company to make chocolate, or you can buy a chocolate machine from a proven chocolate company to make chocolate. Just remember: This machine is the engine of your bean to bar business. You can’t afford to make a bad decision on this piece of equipment.

Choklat is the official North American Dealer for these machines.

You can either get in touch with Clay Gordon here at the Chocolate Life, or contact me directly. He’s been to my factory. He’s seen my equipment, and he’s tasted the product made with it.

Best Regards, and Happy Chocolate Making!

Brad Churchill

CEO.

Choklat

www.Choklat.com

I am amused by the similarity of chocolate and gems in terms of quality assessment. Both are rigorously certified and seriously considered. Take the same gemstone certification (https://gemscience.net/). Or quality control of good chocolate. The situations are almost the same.

sorry but how do a ask a question in the community section?

reply toClosed till the 7th. for Chinese holiday. I was hoping to get it faster. Thanks for rsponding.

reply toThe best suggestion I can give you is to contact the party you purchased your machine from and have them provide you with the support you’re looking for.

I need to get a copy of the manual which gives directions on adjusting the temperature. Can you send me a copy. Clement, house.olando@gmail.com . Thanks !!

Hi Brad. Yes i got it. Then we moved. Then computer crashed…ok it’s all good. Could you please resend it to me again. I am so sorry to ask this. Hope you are well. Heather

Heather@garzasgoodies.com

@Choklat can you please email info to info@borochocolate.com

Hi Heather. I sent you an email. Did you receive it? Cheers. Brad Churchill.

did you order the same 20L size conche? any issues five days later?

That’s interesting Brian. As a dealer I don’t even get them that cheap, and the price certainly doesn’t include shipping (which is about $1000). I am in the process of designing some table top tempering and refining equipment, and knowing what goes into that machine in terms of parts, motor, switches, heaters, controls, and so forth, there is no way the manufacturer made money on that deal. I am actually guessing they lost money if they sold the machine to you for $3,000 landed in the US.

FYI, I ordered one about 3 weeks ago from one of the (many) manufacturers over there. I had to get the motor swapped to a 220VAC single phase. $3000 landed in Houston. We’ll see how that goes! I’ve done quite a bit of importing and don’t expect any issues.

I can’t seem to DM either Choklat or discoverchoc. Could either of you email me brochure and costs to heather@garzasgoodies.com. Thanks Heather

The manufacturer does sell them directly, and I believe they advertise them on Alibaba and other websites like that. If you inquire and you’re in North America, they will simply refer you to me.

Is this one of the ones on Alibaba?

HERE IS A GREAT VIDEO OVERVIEW. NOTE THAT THE FILE IS A BIT BIG (146MB) BUT DEFINITELY WORTH THE WATCH IF YOU ARE INTERESTED IN BEAN TO BAR CHOCOLATE:

https://www.Choklat.com/jmjdemo.html

There is no problem with rust. This was the only photo I had. When the machine first arrives, we recommend flushing it with 10-20 litres of very hot vegetable oil and draining it. This will essentially sanitize the machine and remove any contaminants from the factory. From that point on, as long as you add food safe ingredients to the machine, there is no need to clean it out. Simply flush with cocoa butter between batches. The oil/cocoa butter coats the entire inside of the machine at all times and prevents any oxidation of the metals. It’s only while being manufactured and a bit during transit that oxidation can form. We make several single origin chocolates in these machines and what we do is create a batch (or several) with one origin. Portion out the cocoa butter we would use for a next batch and use that as a flush. Flush the machine and set that cocoa butter aside for the next time we want to make that variety of chocolate. Start with the next batch and a relatively clean machine. There will always be a tiny bit left in the machine, but we’ve found it doesn’t affect the flavour of the new variety. Frankly, having to clean that machine between batches would be a nightmare and experience has told us there really is no need.

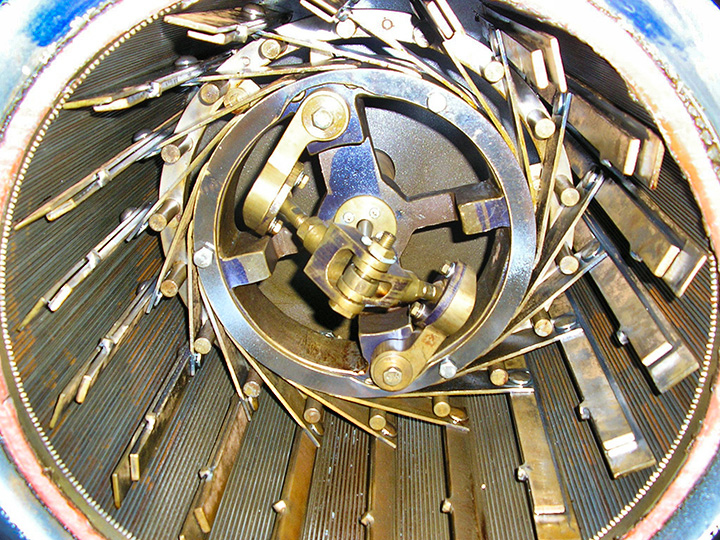

Seeing the inside definitely makes things a lot more clear! Is it a problem with the rust buildup inside the machine? Do you clean that out or does that cause any problems? Speaking of cleanup is it pretty easy to clean them if you happened to have made a flavoured bar and didn’t want to contaminate a single origin?

Brad – you might want to consider a PM program that includes a descaling flush to remove that calcium buildup. Essentially just an acid flush. Helpful to extend the life of your equipment, super easy to do.

Because we don’t stress the machines (even though we use them every day), and the blades and liner are hardened with Manganese 65, there is almost no wear on the internal workings of the machine at all. We have never had issues with breakers, motors, switches or other things. They are to the best of my knowledge, rock solid. The only things we have had to replace are the heating elements for the water jacket, and we did that this fall on all 4 machines. The water here in Calgary is very hard, and we don’t use a recycling system. There was a lot of calcium build up and they burned out. We were able to replace them with hot water tank heaters at a local hardware store for $30 each. I have attached a photo of what the inside of the machine looks like so have a better idea of how it works. We have 4 that we use daily, and a large one that works exactly the same way. The large one makes 2200kg at a time and is over 6 feet tall. Stone wheel melangeurs that make chocolate on a commercial scale haven’t been made in years because this technology is far more efficient and uses less power.

Thanks, that is all super helpful. In the 9 years you have been running these machines what type of maintenance is required, how frequently and what are the costs associated with that? (ie blades needing replaced or sharpened)

@volnoir No pregrinding or preprocessing of any kind is needed (other than roasting and winnowing the beans). Simple dump in the nibs, cocoa butter, vanilla and sugar, and turn the machine on and walk away. That’s it. Obviously for higher intensity chocolate (more viscous) such as 80% plus, or if you want to make straight liquor, you will need to slowly add the nibs in 20lb lots over the course of a half hour or so. Average time from dumping the ingredients in to a final batch will vary depending on the tension you place on the blades and how smooth you want your chocolate to be. We have made silky smooth milk chocolate in as little as 9 hours, but the machine was very loud! Here at Choklat we have standardized a process whereby the machine runs on low tension and refines/conches a batch in 48 hours. Our chocolate is silky smooth and very nicely conched in that time, and the wear on the blades of the machine is almost non existent. Maximum capacity is about 40 litres (40kg), and we can supply the machine in both single phase and three phase 220v. Three phase uses the least electricity. With respect to cost, they are about the same price as the granite wheel melangeurs. I will let Clay contact you directly for pricing out of respect for this being his site, and we have an agreement in place. Clay can also send you a full brochure on the specs. Cheers!

Curious what type of pre-grinding/processing is required before going into one of these machines? Also any additional information on power requirements, average conch time per batch, cost, max capacity?

ChocolateLife members in the Americas are eligible for special discounts by placing orders through TheChocolateLife. DM me @DiscoverChoc .