Chocolate Bars and Hair Dryers

Monday morning I’m back in the chocolate shop and to my surprise, the refiner is still turning. When I left Thursday afternoon, Carmelita believed this batch of chocolate would be ready on Saturday afternoon.

“We had a blackout, Saturday and Sunday.”

Carmelita informed me with resignation in her heart.

“Both days? Why?”

“No. Six hours on Saturday and again for seven hours on Sunday. BEL had work to do on the power lines.”

Belize Electric. I’ll spare you the politics and I despise that term “third world.” So let’s just say Belize’s infrastructure will not reach a higher level of sophistication and reliability until its political leaders allow that to happen. When the power does go out, naturally the chocolate will stabilize in the refiner. And the refiner cannot be restarted when it’s full of stable, stiff chocolate. The chocolate must first be warmed… with a hair dryer. Saturday afternoon, when the power returned, she plugged in her trusty Clairol blow dryer and spent thirty minutes using it on the outside of the steel drum. As the chocolate softened, she clicked the start-stop button of the refiner for a few seconds at a time until the wheels turned freely. She left Saturday afternoon with the refiner turning and believed she would make bars on Sunday. And when she returned Sunday morning once again there was no power. She covered the refiner with a cloth and came in early Monday.

Thursday the week prior we had 50 pounds of freshly ground clean nibs that went from the grinder to the refiner. At Ixcacao we have a small room used for tempering, molding, and packaging. And it’s the only room in the shop that’s air-conditioned. And now the chocolate in the refiner is finally ready to be molded into bars. Sort of. While in the final stages of refining, the chocolate is averaging 115 degrees. Carmelita has turned off the heat on the refiner and let the chocolate drop down to about 110. Meanwhile I’ve plugged in the small tempering machine to warm it up.

In order to stabilize the chocolate, there’s a slow-moving process to make it bar ready. Resembling an Instapot, the drum of the small tempering machine slowly rotates while the chocolate, about two quarts at a time, cools down to 84 degrees, then warms the chocolate back up to 89, then back down to 84, then back up to 89, then back down to 84, and once again back to 89 degrees. It’s a rather slow process and while this was going on, I was sifting cacao powder. At Ixcacao there’s always cacao powder to sift. The local brewery uses our cacao powder to make its chocolate stout, and in Belize, cacao has a nine-month growing season.

Consequently, Juan, Carmelita, and the rest of the Ixcacao team are constantly processing cacao beans and if there aren’t bars to make, there’s powder to sift and package. Some days I leave here coated in a fine layer of powder.

Every time I walk into the shop, or to Abelina’s kitchen, it is sensory overload. The kitchen is second floor, open air. Across the street is the greenest mountain I’ve ever laid eyes on. In the US we cannot stand the sight of a green, bare mountain. Like a Christmas tree without ornaments, our mountains back home beg for chintzy decorations. Houses, roads, power lines, antennae, signage, and non-native grasses are required décor of your mountain. In San Felipe, however, the mountains are treasured and respected. And those mountains create incredible aromas of life. The complexity of the chocolate’s aromas compete with the mountain’s on a daily basis. Some days there’s a mild breeze, and it makes the mountain positively dance. And when the Howler Monkeys are upset and voicing their disapproval of my clumsy chocolate methodology, the mountain looks and sounds like a massive green animal.

“Chef!”

It’s Carmelita hollering, snapping me out of my reverie. Finally, the chocolate is ready. Carmelita invites me to give it a spoon test. After the third trip from 84 to 89, I dip the tip of a stainless-steel spoon into the chocolate then place the spoon on the cooling rack. Less than five minutes later we tap the chocolate with the tip of our fingers. If the chocolate stains our finger or melts the chocolate on the spoon it must make another trip around the dial, if not it’s time to make bars. When we tap the spoon, we leave a shiny mark on the chocolate. Damn. Off to sift cacao powder. Fifteen minutes later I’m back and this time the chocolate is ready, maybe. She has a spoon she’s dipped in and it’s cooling and she believes it’ll be good. Carmelita tells me the exercise of taking the chocolate back and forth from 84 to 89 several times over is crucial as we’re aligning the crystals which makes the chocolate shelf stable.

“You mean like the fortune teller does with the glass ball?

Carmelita rolls her eyes.

“Go wash your hands please and dry them carefully. See? The chocolate is ready.”

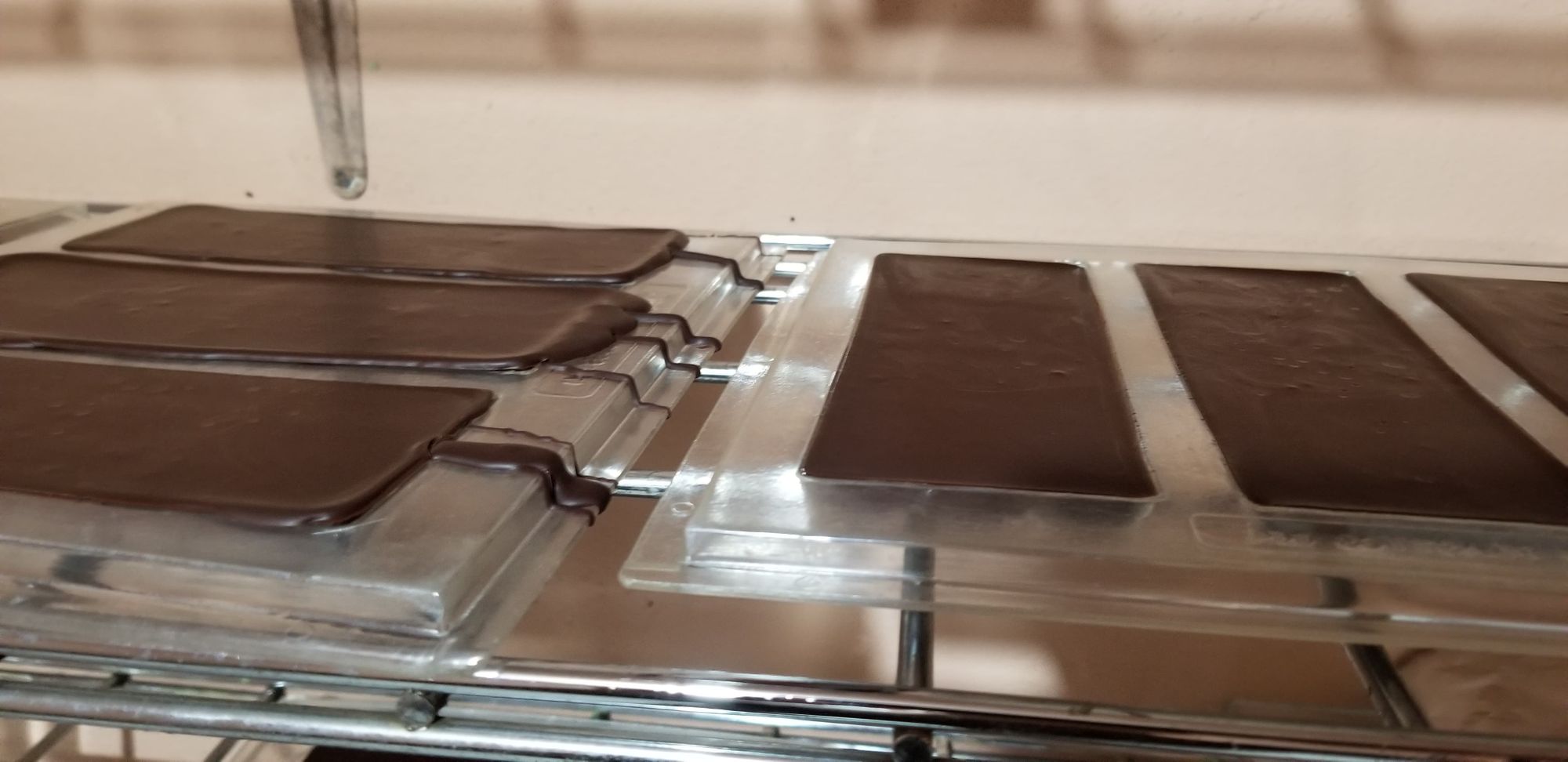

We both tap the end of the spoon and the chocolate doesn’t smear, doesn’t shine. Carmelita has a stack of bar molds ready upon my return from the sink. She dips into the warm chocolate, twirls the ladle as she lifts it out and spoons the warm chocolate into the mold. Three dips then she taps the molds on the counter. Tap. Tap. Tap. She gives the mold a tilt this way, a tilt that way then places it on the cooling rack. My turn. I want to emulate Carmelita’s smooth actions immediately and instead end up dripping 89-degree chocolate on the counter and my sleeve but manage to get enough into the mold.

Carmelita used to do this with a gram scale but now uses her eyes. It took too long to scoop chocolate and weigh, scoop and weigh so now her three individual scoops are precise enough to make each bar at 3.5 ounces. We manage to get 18 bars made and set on the racks. Carmelita invites me to look under the rack at the molds. As the chocolate cools, it pulls away from the plastic and leaves a tiny bit of space between the bar and mold.

In thirty minutes, we’ve spooned the chocolate into bars, filled the tempering machine again and are readying the bars for packaging into their gold foil. The week prior we had cut numerous individual packages of foil and the labels. Soon we have the bars in and all that’s left is for her to use the heat seal on the end of the package while I get the labels on.

“And now you’ve made chocolate bars, Chef Malik.”

“Yeah. I guess I have.”